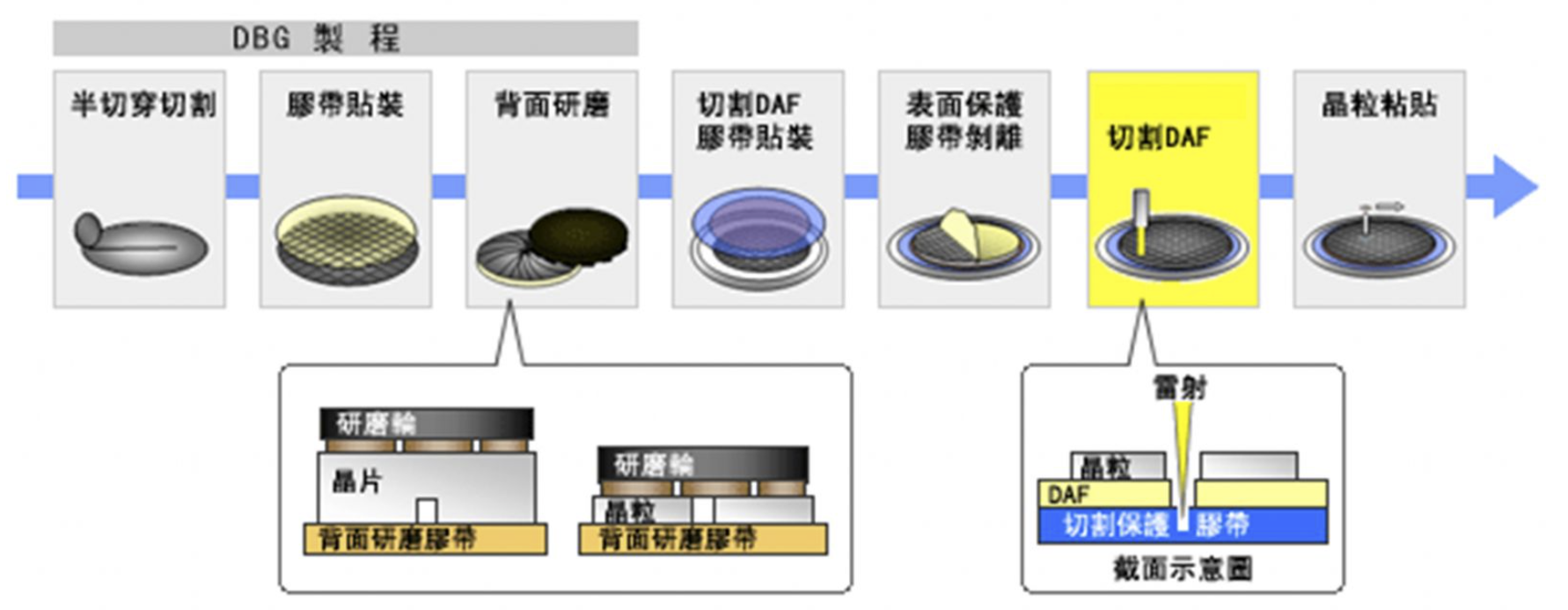

DAF Film Introduction:Die-Attach-Film, wafer bonding film, the purpose is to cut and separate the wafers together during laser cutting, and peel off, so that the cut wafers (Die) can still be adhered to the film without being cut due to cutting Resulting in random arrangement.

DAF Film Features:

1) Excellent electrical and thermal conductivity.

2) It can be used with advanced cutting processes, such as DBG and SDBG.

3) Excellent stripping performance.

4) Excellent chip cutting performance.

5) Strong adhesion, can be used for high-speed wafer lamination processing.

6) It can be matched with UV or non-UV cutting tape.

7) Excellent workability, no chip ejection problems.

8) Excellent wire covering and surface covering ability.

The thinning wheel plays an important role in the chip preparation process. On the one hand, the thinning process can reduce the overall thickness of the chip, which is beneficial to heat dissipation and integration; on the other hand, it can reduce the thickness and surface roughness of the wafer surface damage layer, and release The internal stress accumulated in the wafer caused by each process before thinning reduces the degree of collapse of a single chip during the dicing process.

The grinding wheel is a round consolidated abrasive tool with a through hole in the center, which is made by adding a bonding agent to the abrasive, and then forming a compact, drying and sintering. Diamond grinding wheels are mainly made of diamond as the main abrasive, which is then combined and formed by a bond. The bond is roughly divided into three types: metal, resin, and ceramic. Cup-shaped metal bond diamond grinding wheels are mainly used for the back grinding of wafers, and the diameter is generally 200-350mm.

SiC and Si3N4 third-generation semiconductor materials have the characteristics of high hardness, high brittleness, and easy burns, which makes it difficult to meet the processing requirements of traditional ceramic bond, resin bond and metal bond diamond grinding wheels. Composite bonding agent (metal/resin, metal/ceramic composite bonding agent) combines the advantages of the two types of bonding agents. At present, the metal-resin composite bonding agent that has been studied more has long life, good self-sharpening, small deformation and processing quality High advantages, showing excellent performance in the processing of precision ceramic parts. The composite bond diamond grinding wheel has broad application prospects in the thinning of third-generation semiconductor materials.

ADD: 1605, 16th Floor, Guoxin Investment Building, Gaoxin South 7th Road, Yuehai Street, Nanshan District, Shenzhen

TEL: 16620843991E-MAIL:minna@miamaterials.com

© 2021 Shenzhen Jinglirong Electronic Materials Co., Ltd. All rights reserved 粤ICP备2021172720号